You can come to us with a concept or an idea, a functionality that you would like to achieve or performance criteria for some equipment, a sketch or even the complete design, we are equipped to take on your requirements either through our expert in-house team and/or our empanelled design partners.

We would be happy to develop any design ground up, conduct FEM analysis, work on design approvals, develop manufacturing drawings, generate prototypes or 3D models, cater to your other specific requirements.

Some significant turnkey projects (that included design) undertaken by us in the past include Armoured Special Purpose Vehicles, Mobile Shelters, Deck Loading Barge, Ground support systems for DRDO programs and many more.

Article Loading Trolleys

Article Loading Trolleys Assembler cum Transporter

Assembler cum Transporter  150T Deck Loading Barge

150T Deck Loading BargeShiva Engineering provides an ideal mix of technical capabilities, state of the art equipment and high-quality standards. Our facilities are well equipped to efficiently and cost effectively in the fastest possible time execute critical metal fabrication processes.

CUTTING – Depending upon the requirement, we use a range of methods for cutting metal such as sawing (powersaw & bandsaw) shearing, plasma cutting, oxy-acetylene CNC cutting, punching, boring, drilling etc. Our CNC cutting machine has a table size of 5 metres by 2.5 metres and can cut mild steel up to 150mm thickness

FORMING – Our brake presses, corrugating, rolling and bending machines effectively cater to most metal forming processes such as roll, bend, shape, corrugate etc.

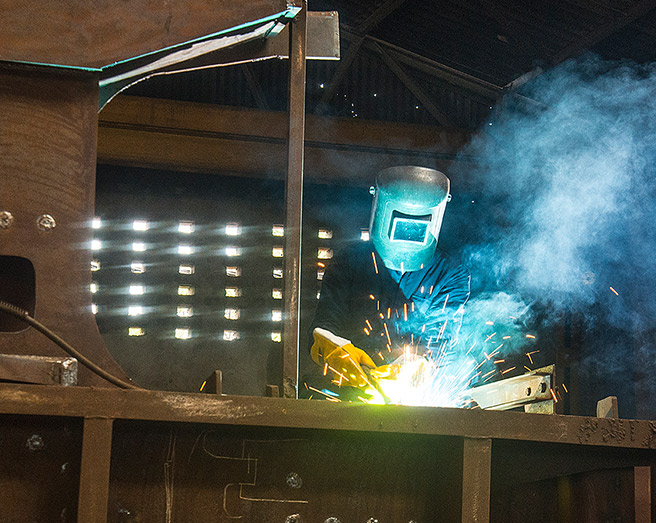

ASSEMBLY – In line with relevant codes, ISO welding requirements and customised Welding Procedure Specifications (WPS) for each product, our qualified and trained welders meticulously work on achieving the required strength and finish in every assembly operation. The welding process could be TIG welding, MIG welding and/or ARC welding. NDT tests form an integral part of this operation and maybe done by Dye Penetration/Radiography. ultrasound or other suitable options.

Besides welding, we are also adept to perform other assembly operations such as riveting, fastening etc.

To ensure accuracy & consistency in repeatability, customised jigs and fixtures are used during the fit-up process.

FINISHING – Finishing operations such as sand blasting, shot blasting, powder coating, galvanizing, painting etc. are either done in house or by our reliable partners under strict supervision of our experts.

Based on client requirements and specification, our teams of experts from diverse fields have managed to integrate items manufactured at our factory with several systems including hydraulic, pneumatic, electrical, conveyor system, control systems, driving arrangements etc. to result in sophisticated equipment for several applications. Our engineers have tirelessly worked on these projects to ensure highest level of build quality, smooth and effortless integration as well as optimum performance of the final product/equipment.

We also undertake field installation work where the project is a combination of in-house manufacturing and site work.

If you want a single-window solution for any such requirement, please feel free to contact us. Some of our significant projects that required integration/installation include Mat Ground Surfacing CL70, Barge, Control Pulpits, Mobile Shelters, Ground support systems etc. These are a few projects involving integration/installation.

Control Pulpit at Tata Steel

Control Pulpit at Tata Steel Dummy Cylindrical Object

Dummy Cylindrical Object Mat Ground Class 70

Mat Ground Class 70Our 3 axis Vertical Milling Centre can handle operations such as drilling, tapping, contour milling, face milling, edge preparation etc. with a high level of precision with a fast turnaround time. Materials up to 6m long, 2.5m wide and 1.2 m high can be loaded on the table and the main application of the end products are primarily in Defence, Railways, Aerospace, Power & Energy sectors.

Additionally, our conventional machine shop is equipped with lathes, shaping and planing machines etc. to cater to other diverse needs of the sectors we serve.